the blue fabric above can easily fetch up to 150SGD.

this green one costs about 100SGD.

i can never understand why people are willing to pay. that is, until today.

----------

our second day in Ban Kok Muang was spent mainly in learning the process of Thai Silk making. honestly, it doesnt interest me much. 不就是很多線在一起。😒

so i was kinda wishing that i was in a more interesting village. like the always popular and very populated chiangmai, or the mountainous regions of chiangrai with hill tribes aplenty...

after today's session, i have nothing but respect and admiration for the people behind the scene.

lets start from the final product.

the fabric <-- the thread <-- the WORM.

before you scroll any further, i need to warn you. the following picture may cause discomfort. 😱

YOU

HAVE

BEEN

WARNED

these tiny creatures are the ones that die for your silk.

they are fed till they grow to the right size..

then placed in water to boi................😰

okie its quite gruesome.

i shall skip the entire process.

TADA! you have your silk thread.

and its white.

so the next step is to dye the yarns.

there are chemical dye process and the au-naturale process.

if patterns/designs are involved in making the fabric, then there is a lot more work to do then just jumping straight into weaving.

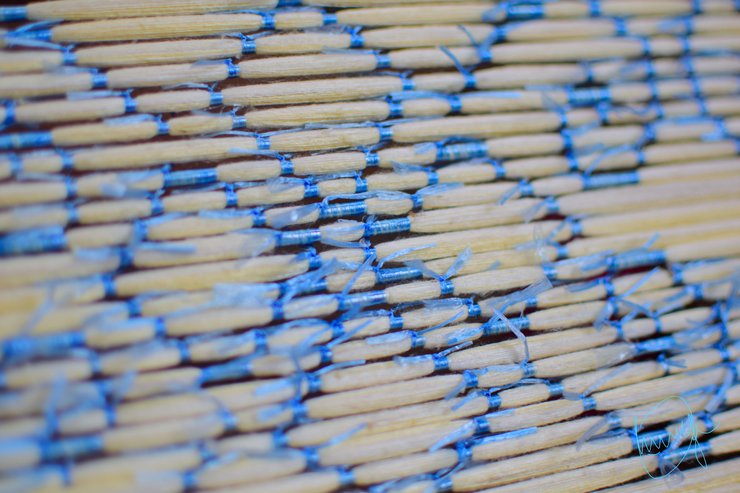

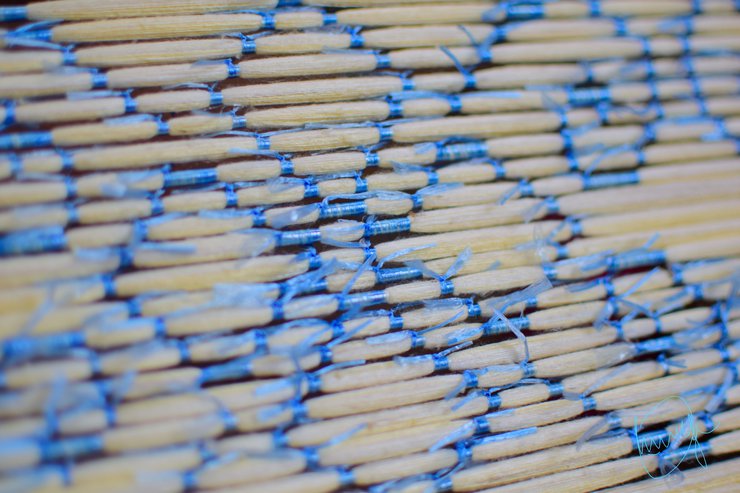

the silk yarns are bundled up. certain parts are then 'covered' up.

a lot of precision is needed in this process.

once the desired pattern is 'covered', they are sent for dyeing.

after they dry up, the covered areas are removed.

another process that requires a lot of patience.

TADA!!!!! so now you see the design. BUT THIS IS NOT ALL.

the steps of covering/dyeing/removing are repeated for EACH OTHER.

so basically its like...

you want white, yellow, red and blue.

so step one, you cover all the white, red and blue parts. then you dye the entire thing with yellow.

then you cover up the yellow part, remove the red part. then you dye it red.

then you cover up the red part, remove the blue part to dye it blue.

this whole process is SO DAMN TIRING.

finally, when all the dyeing is done, they are spun out. and 101% accuracy in measurement is required.

then they are all spun out on the spool for the last part.

there are 4000 threads in these fabric!!!!!

the weaving process takes a lot of patience as well.

i dont even have the patience to write all of it down.

just know that she has to put the yarns from left to right, switch the top and bottom, then push the yarns tightly then put the yarns back from right to left, then switch the bottom and top, then push the yarns tightly...

blearghhhh i dont even know how to explain. you really need to sit down and do then you will understand how complicated it is.

it is a very laborious process that takes a lot of patience, persistence, precision and perseverance.

as you can see, the people preserving this trade are getting old and young people are less willing to work in such trade.

so at the end of the day, just know that this is a skill that should be appreciated.

because that one day, this skill may be replaced by robots.

when that time comes, no price will be able to bring this trade back.

Trees by the Sea

Friday, July 26, 2019 12:05 AM